PLC Repair Essentials

In the bustling world of industrial automation, maintaining equipment efficiency is non-negotiable. As a cornerstone of this industry, programmable logic controllers (PLCs) are critical components that require regular repair and maintenance. A qualified PLC repair company like AFSub Soft ensures these systems function flawlessly. With their specialized services, clients can expect a blend of expertise, precision, and promptness.

PLCs regulate machinery processes, making their smooth operation vital for productivity. Issues like hardware malfunctions or software glitches can cause significant downtimes, affecting overall outputs. By providing comprehensive inspection and diagnostics, AFSub Soft stands ready to tackle such challenges, ensuring business continuity.

Choosing a reliable PLC service partner involves understanding their capacity to handle diverse PLC brands and models. Expertise in troubleshooting and firmware updates is a must. AFSub Soft offers this and more, providing clients with peace of mind and operational efficiency.

Why HMI Repair Matters

Human Machine Interface (HMI) devices form the bridge between machine and operator, making their optimal performance crucial. A malfunctioning HMI can disrupt communication, leading to productivity losses. When seeking a PLC repair company that also specializes in HMI repairs, it’s essential to choose one that addresses such challenges expertly.

AFSub Soft excels in diagnosing and repairing HMI issues, ensuring seamless user interaction with machines. Their team can handle a vast array of HMI devices, from touch screens to control panels, restoring functionality efficiently. This commitment to reliability makes AFSub Soft a preferred choice for HMI repairs.

VFD Repair Services Importance

Variable Frequency Drives (VFDs) are indispensable in controlling motor speed and improving energy efficiency. However, like any advanced technology, VFDs require expert handling to maintain their operational status. A specialized PLC repair company such as AFSub Soft provides exceptional VFD repair services, crucial for uninterrupted industrial operations.

With their intricate understanding of electronic drive systems, AFSub Soft’s professional team quickly identifies and remedies VFD issues. Their service not only prolongs the lifespan of the equipment but also maximizes energy efficiency, resulting in significant cost savings for businesses.

Preventative maintenance is another critical aspect offered by AFSub Soft. Regular checkups can mitigate potential failures, ensuring your systems remain reliable and efficient.

PCB Drive Repair Specialities

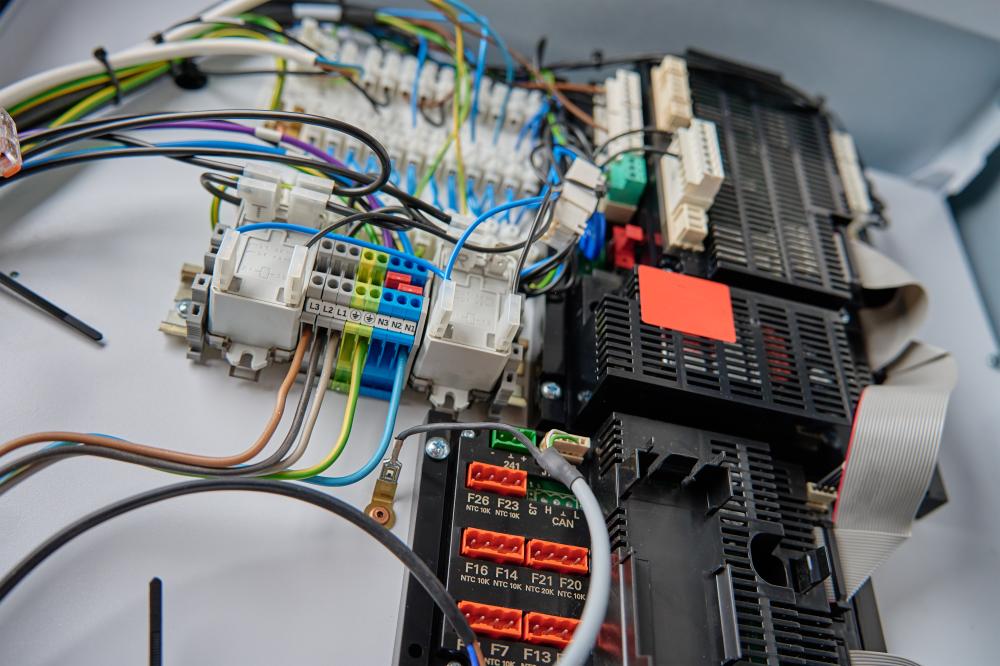

Printed Circuit Board (PCB) drives are integral to the smooth functioning of electronic systems. When these components falter, a prompt and precise repair service is necessary. AFSub Soft, with its in-depth expertise, offers exemplary PCB drive repair services, restoring these critical components to their optimal state.

Repairing PCB drives demands a meticulous approach and a thorough understanding of electronic pathways. AFSub Soft’s technicians excel in identifying issues, whether they are due to physical damage or electronic malfunction, ensuring minimal downtime and efficient service delivery.

Benefits of Soft Starter Repairs

Soft starters regulate the power flow to motors, ensuring smooth startups and prolonging motor life. When these devices malfunction, they can lead to mechanical stress and inefficiencies. Engaging a competent PLC repair company like AFSub Soft for soft starter repair ensures your systems maintain their integrity and efficiency.

AFSub Soft provides comprehensive repair services, addressing common issues like voltage spikes or software problems. Their technicians are adept at restoring soft starters promptly, reducing the risk of further mechanical issues.

Moreover, their service includes detailed diagnostics and routine checks, essential for the longevity and reliability of soft starters in industrial settings.

Understanding the nuances of soft starter systems allows AFSub Soft to offer not only repairs but also insightful recommendations for system improvements and upgrades.

AC Inverter Drives Repair

AC inverter drives are pivotal in controlling AC motor speed and torque for varied industrial applications. Their repair and maintenance are crucial for optimal performance. A distinguished PLC repair company such as AFSub Soft provides top-notch AC inverter drive repair services, ensuring your systems run efficiently and effectively.

AFSub Soft’s experienced team performs rigorous diagnostics, enabling them to pinpoint issues accurately. Whether it’s component failure or software glitches, their comprehensive approach guarantees a swift return to full operational capability.

In addition to expert repairs, AFSub Soft offers preventive maintenance strategies, safeguarding against potential future disruptions and ensuring consistent system performance.

Choosing AFSub Soft

When searching for a PLC repair company that offers a gamut of electronic repair services, selecting a provider like AFSub Soft promises peace of mind and reliability. With expertise spanning across PLC, HMI, VFD, and PCB repairs, AFSub Soft is a hub of excellence and efficiency in Mumbai’s industrial electronics repair sector.

The company’s dedication to customer satisfaction is reflected in their round-the-clock availability and rapid response times. With trained professionals ready to address all repair needs, AFSub Soft has built a reputation on trust and success stories.

By choosing AFSub Soft, you are partnering with a team that values precision and customer satisfaction, ensuring every repair not only meets but exceeds industry standards.

Client Testimonials

Real-world experiences underscore AFSub Soft’s commitment to excellence. Rajesh K., an Operations Manager, applauds their exceptional PLC repair services, highlighting their ability to diagnose and resolve issues expediently. This testimonial is a testament to AFSub Soft’s prowess in the industrial electronics repair domain.

Salik Devendra, Technical Director, shares his satisfaction with AFSub Soft’s HMI and drive repairs. He notes that their technicians’ knowledge and efficiency ensure machines remain operational without extensive downtimes, affirming the reliability of AFSub Soft’s services.

Can a PLC be repaired?

Absolutely, PLCs can be repaired, and that’s where AFSub Soft excels. With our specialized team of experts, we are equipped to handle a wide range of issues, from hardware malfunctions to software glitches. Picture this: your manufacturing line suddenly comes to a halt due to a PLC problem. Our team can diagnose and fix the issue, ensuring minimal downtime and restoring your operations. We focus on providing tailored solutions that not only fix the immediate problem but also enhance the overall performance of your systems.

How do you solve a PLC problem?

Solving a PLC problem involves a thorough diagnostic process, which our team at AFSub Soft is highly skilled in performing. We start by understanding the symptoms and then use advanced diagnostic tools to pinpoint the exact issue. It’s much like detective work; sometimes the problem is hidden beneath layers of code or intricate circuitry. After identifying the cause, we implement a strategic fix, which often includes hardware repair, firmware updates, or rewiring. We ensure that our solutions are not just stopgaps but sustainable fixes that keep your operations running smoothly. Have you ever wondered how a small issue can affect your entire production line? Our proactive approach prevents such scenarios.

What is the life expectancy of a PLC?

The life expectancy of a PLC typically ranges from 10 to 20 years, depending on factors such as brand, usage conditions, and maintenance practices. However, with regular maintenance and timely repairs from a reliable partner like AFSub Soft, this lifespan can be extended significantly. Consider your PLC systems as the heartbeat of your production lines; with proper care and attention, they continue to perform at optimal levels. We offer preventive maintenance services that help identify potential issues before they become significant problems, thereby extending the lifespan of your equipment.

What does a PLC technician do?

A PLC technician is a specialized professional who is adept at troubleshooting, repairing, and maintaining PLC systems. At AFSub Soft, our technicians are more than just repairmen; they are system optimizers. They analyze system performances, troubleshoot problems, and perform essential upgrades. Imagine a scenario where your production efficiency suddenly drops. Our technicians step in to diagnose the problem, whether it’s a software bug or a hardware malfunction, and implement a solution that not only restores functionality but might also enhance performance. We’re proud to say that our team’s skills and dedication are key reasons why our clients trust us with their valuable equipment.

Why choose AFSub Soft for your electronic repair needs?

Choosing AFSub Soft means opting for reliability, expertise, and efficiency. As the premier electronic repair company in Mumbai, we offer around-the-clock service to ensure your operations face minimal interruption. Our services cover a broad spectrum, from PLC and VFD repairs to HMIs and PCB drives. Our team comprises highly trained professionals who bring both knowledge and a personalized touch to every repair project. Imagine a team that not only knows your equipment inside out but also responds swiftly to emergencies, providing peace of mind and boosting productivity. Why not experience it for yourself? Reach out for an assessment of your repair needs.

How does preventive maintenance extend the life of industrial equipment?

Preventive maintenance is crucial for extending the life of your industrial equipment, and AFSub Soft is committed to this approach. Imagine preventive maintenance as a regular health check-up for your machines. By conducting routine checks and diagnostics, we identify and address issues before they escalate. This proactive approach prevents costly breakdowns and enhances the longevity of your equipment. Our team implements customized maintenance schedules that ensure your machinery operates at peak efficiency. Interested in learning how we can tailor a maintenance plan for your specific needs? Let’s discuss how preventive strategies can add years to your equipment’s lifespan.

Resources

- Rockwell Automation – Rockwell Automation is a leading provider of industrial automation solutions, offering a wide range of products and services to optimize manufacturing processes.

- National Electrical Manufacturers Association (NEMA) – NEMA is the association of electrical equipment and medical imaging manufacturers, promoting standardization and safety in the industry.

- American National Standards Institute (ANSI) – ANSI oversees the creation, promulgation, and use of thousands of norms and guidelines that directly impact businesses in nearly every sector.

- Omron Corporation – Omron is a global leader in industrial automation, providing innovative solutions to enhance manufacturing processes and improve productivity.

- Automation.com – Automation.com is a leading online publisher of automation-related content, offering news, articles, and resources for professionals in the industry.