The Importance of HMI Systems

At AFSub Soft, we’ve seen firsthand how critical Human Machine Interfaces (HMIs) are in the industrial sector. These interfaces serve as the primary point of interaction between humans and machines, facilitating seamless operations and efficient control of automated processes. Whether it’s in a manufacturing plant or at a power station, HMIs offer the essential link that ensures humans can monitor, evaluate, and adjust machine functions effectively.

Human-machine interactions occur in numerous forms, from basic display screens to sophisticated touchscreens featuring real-time analytics and control options. The reliability and efficiency of these systems can significantly impact productivity, safety, and operational costs. Failure to maintain and repair these interfaces promptly can lead to costly downtimes and operational disruptions.

Key Services Offered

Our expert team at AFSub Soft provides a comprehensive range of services focused on industrial automation electronics, including HMI Repairing Service. We cater to an array of needs, from minor touch panel repairs to major overhauls of HMI systems. Our services ensure that your operational devices remain in peak condition, reducing the likelihood of downtimes.

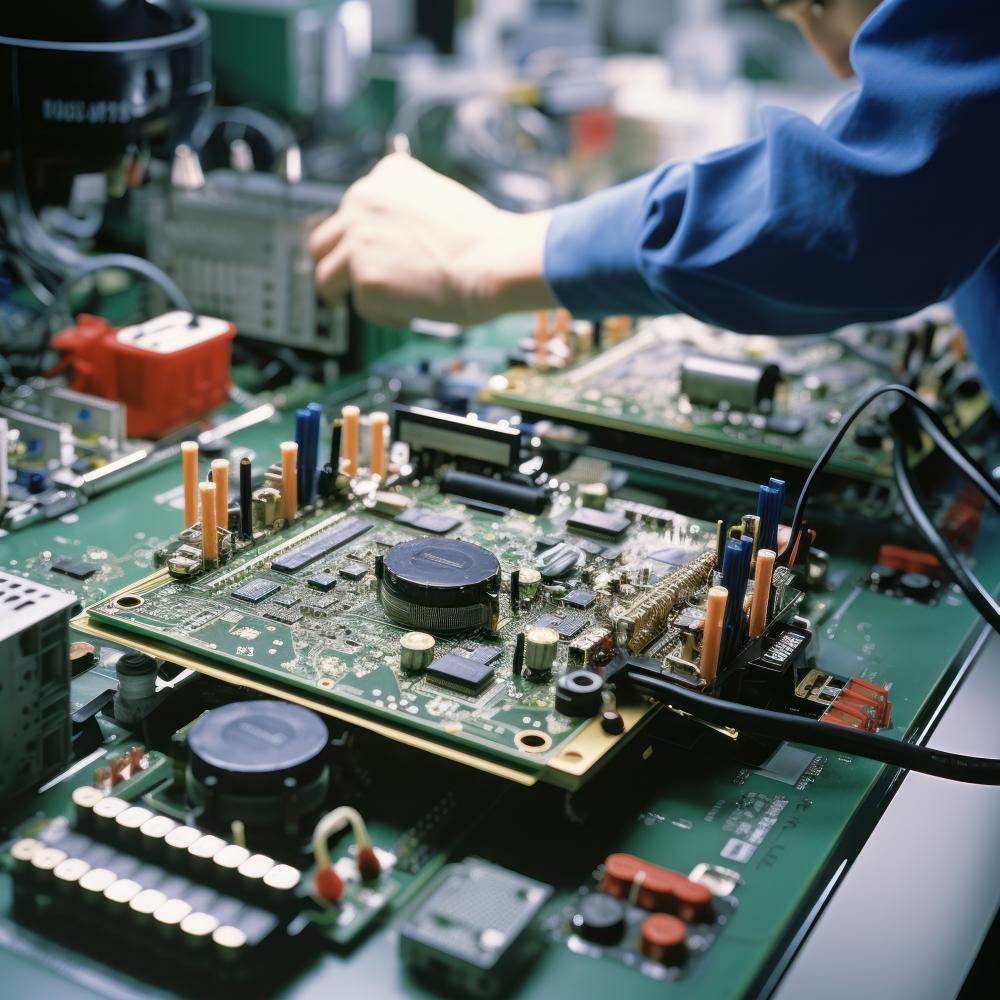

Understanding the intricacies of each component, our team excels in diagnosing and repairing various electronic elements. Whether it’s reprogramming a malfunctioning unit or replacing defective parts with high-quality alternatives, our commitment to quality ensures optimal performance for your systems. Our engineers are adept in handling complex machinery, offering solutions that are both innovative and reliable.

In addition to HMI repairs, AFSub Soft specializes in a multitude of services such as PLC, VFD drive, and circuit board repairs, providing holistic support for your industrial electronic needs. By choosing AFSub Soft, you gain access to a wealth of experience and expertise for maintaining operational efficiency.

Innovations in HMI Repair

Over the years, technological advancements have transformed HMI systems, integrating more sophisticated features and capabilities. At AFSub Soft, we have embraced these innovations, allowing us to offer cutting-edge repair services that keep your systems updated and efficient. By leveraging the latest tools and technologies, we ensure that your equipment is not only repaired but also enhanced to meet future operational demands.

The adoption of predictive maintenance tools enables our technicians to foresee potential issues before they disrupt operations. This proactive approach helps in minimizing downtime and extending the lifespan of your HMI systems. Implementing smart diagnostic technologies, we identify weaknesses and vulnerabilities, ensuring they are addressed promptly and effectively.

Our commitment to innovation ensures that your systems are not just restored to their original functionality but are also optimized for enhanced performance, safety, and reliability.

The HMI Repair Process

Initial Diagnosis

When you contact us for an HMI Repairing Service, our first step is a comprehensive assessment of the device. This involves analyzing the symptoms, running diagnostics, and identifying faults within the system. Our technicians use state-of-the-art diagnostic tools to ensure no underlying issues go unnoticed.

Repair and Replacement

Following diagnosis, the repair process involves either fixing the faulty components or replacing them with superior alternatives. We keep a substantial inventory of replacement parts to expedite this phase, minimizing any delays in the repair process. Our skilled technicians ensure that each repair is executed with precision and attention to detail.

Testing and Quality Assurance

Post repair, each HMI undergoes rigorous testing to verify its functionality and performance. We conduct stress tests under simulated operational conditions to ensure the system meets all performance benchmarks. Only after passing these stringent assessments is the device cleared for return to service, guaranteeing reliability.

Industry-Specific Requirements

Different industries have distinct operational demands and standards, and at AFSub Soft, we tailor our HMI Repairing Service to meet these unique requirements. In sectors such as pharmaceuticals, food processing, and automotive manufacturing, stringent regulatory standards must be adhered to. Our repair solutions are crafted to comply with such industry regulations, ensuring seamless integration and operation.

We understand that certain environments, like chemical plants or water treatment facilities, require HMIs that can withstand harsh conditions, including extreme temperatures, vibration, and potential exposure to chemicals. Our solutions are designed to enhance the durability and resilience of HMIs, aligning with specific industry needs and operational environments.

Customer-Centric Approach

Personalized service is at the heart of our operations at AFSub Soft. We believe that understanding each client’s unique challenges and requirements is essential for delivering effective solutions. Our customer-centric approach ensures that we work closely with clients, offering customized repair strategies and round-the-clock support.

Our dedication to excellence is reflected in our customer testimonials. Satisfied customers appreciate our quick response times, expert problem-solving, and commitment to minimizing downtime. This personalized engagement ensures that each client feels valued, understood, and confident in the solutions we provide.

For us, success is measured by the satisfaction of our clients and the smooth operation of their systems. By fostering open communication and collaboration, we ensure that we meet and exceed customer expectations at every turn.

How to Maintain HMIs and Prevent Failures

Maintenance plays a crucial role in preventing HMI failures and ensuring long-term reliability. Based on our experience at AFSub Soft, we advocate for a regular maintenance schedule, which includes periodic inspections, cleaning, and software updates. Such proactive measures can significantly reduce the risk of unexpected breakdowns.

Operators should be trained to identify and report any signs of wear or malfunction promptly. Issues like slow response times, flickering screens, or unresponsive touch panels should be addressed immediately to prevent further complications. Keeping abreast of software updates and implementing them as needed is vital to avoid vulnerabilities and enhance system capabilities.

- Schedule regular inspections and cleaning to ensure optimal performance.

- Update software periodically to prevent obsolescence and vulnerabilities.

- Train staff to recognize early signs of wear or failures.

Competitive Advantage of AFSub Soft

Positioned as a leader in the industry, AFSub Soft’s competitive advantage lies in our dedication to quality, innovation, and customer satisfaction. Our comprehensive approach to HMI Repairing Service encompasses not just fixing issues but also upgrading and optimizing HMI systems to deliver superior performance.

Our team of highly trained technicians and engineers brings a wealth of expertise and experience, ensuring that every repair is handled with the utmost professionalism. Our around-the-clock availability underscores our commitment to minimizing client downtime and maximizing productivity. We stand out as a trusted partner for businesses seeking reliable and efficient electronic repair services.

Our track record of success and satisfied clientele is a testament to our unwavering commitment to quality and innovation, positioning us as the go-to solution provider for all industrial electronics repair needs in India.

Can an HMI module be repaired?

Absolutely, an HMI module can often be repaired, and that’s something we specialize in at AFSub Soft. The repair process typically involves diagnosing the problem, whether it’s a software glitch, a hardware malfunction, or a display issue. Once the issue is identified, we either repair or replace the faulty components. It’s like restoring a classic car; with the right expertise, these systems can often be brought back to life. We have seen countless cases where a timely repair saved significant costs compared to replacing the entire unit. If you’re experiencing issues with your HMI, it’s worth reaching out to discuss your options.

What is HMI in maintenance?

HMI in maintenance refers to the role of Human Machine Interfaces in the upkeep of industrial operations. These interfaces are crucial for monitoring and controlling machinery, ensuring systems run smoothly. At AFSub Soft, we emphasize the importance of regular maintenance for HMIs to prevent failures. Maintenance activities include routine inspections, cleaning screens, and updating software. Just like maintaining a vehicle, consistent care keeps your HMI reliable and efficient. If neglected, small issues can evolve into significant problems, leading to downtime and loss of productivity.

What does HMI mean?

HMI stands for Human Machine Interface, which is essentially the bridge between operators and machinery. It allows for user-friendly interaction with complex industrial systems, enabling monitoring and control of processes. Think of it as the dashboard in your car, providing critical information and controls at your fingertips. At AFSub Soft, we not only repair HMIs but also help enhance their functionality to meet modern industrial needs. We ensure your interfaces remain intuitive and efficient, supporting your operations seamlessly.

How can I ensure the reliability of my HMI systems?

Ensuring reliability in your HMI systems involves a combination of regular maintenance and prompt repairs. At AFSub Soft, we recommend implementing a proactive maintenance schedule, which includes cleaning, software updates, and inspections. Training your staff to recognize early warning signs of wear or malfunction is also crucial. For example, if an operator notices a screen flickering or delayed responses, these should be addressed immediately to prevent further issues. By keeping your systems in peak condition, you can maximize uptime and efficiency. Have you checked your maintenance plans lately? It might be time for a review.

What innovations are improving HMI repair services?

In recent years, HMI repair services have greatly benefited from technological advancements. At AFSub Soft, we’ve adopted innovative tools like predictive maintenance technologies, which allow us to foresee potential issues before they disrupt operations. Smart diagnostic systems help in quickly identifying vulnerabilities, ensuring timely and effective repairs. These innovations not only restore functionality but also optimize systems for future demands. I liken it to having a mechanic who not only fixes your car but tunes it for better performance. Staying ahead with cutting-edge tools keeps your systems running smoothly and efficiently. What innovative tools have you adopted in your operations?

What industry-specific requirements should be considered in HMI repair?

Industry-specific requirements play a critical role in how we approach HMI repair at AFSub Soft. Different sectors, like pharmaceuticals, automotive, or food processing, have unique standards and regulations. For instance, HMIs in chemical plants need to withstand harsh conditions such as extreme temperatures and exposure to chemicals. Our repair solutions are tailored to meet these specific needs, ensuring compliance and durability. By understanding the operational environment, we enhance the resilience and effectiveness of your HMIs. It’s essential to align repairs with industry demands, and we are equipped to navigate these intricacies. Does your industry have specific challenges you’d like to discuss?

Resources

- Occupational Safety and Health Administration (OSHA) – The official website of OSHA provides information and resources related to workplace safety and regulations.

- National Fire Protection Association (NFPA) – NFPA offers standards and guidelines for fire safety and prevention in various industries.

- Environmental Protection Agency (EPA) – The EPA website offers information on environmental regulations and best practices for industries.

- National Institute of Standards and Technology (NIST) – NIST provides resources for technology, measurements, and standards to enhance industrial processes.

- Engineering Toolbox – A comprehensive resource for engineering information, calculations, and tools for various industrial applications.