The Importance of A Professional Industrial PCB Repair

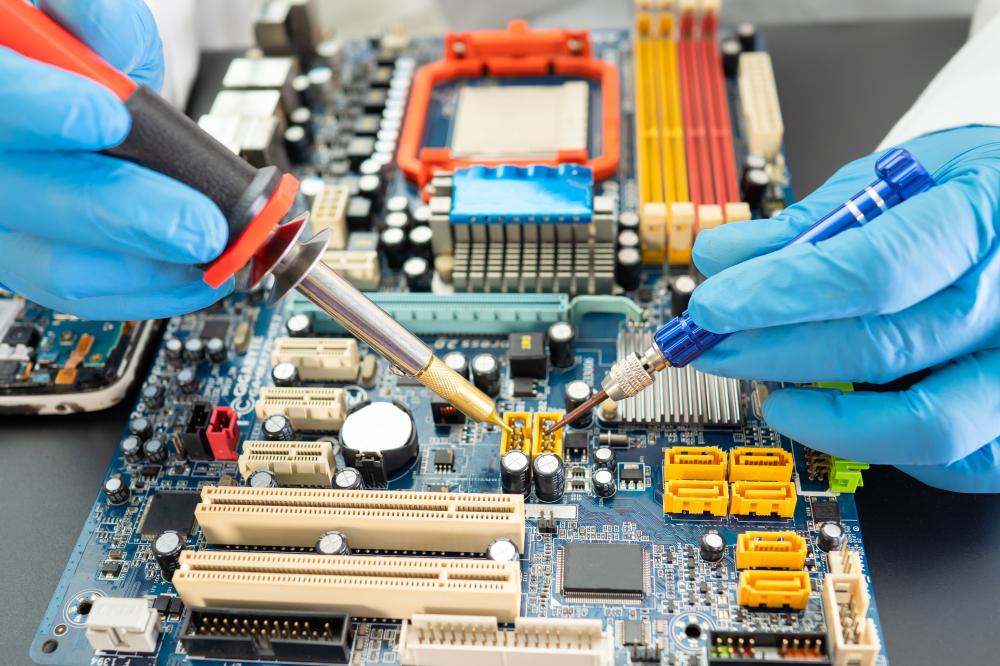

In the heart of Mumbai, PCB repair plays a critical role in maintaining the integrity of industrial automation systems. At AFSub Soft, we understand the demands of keeping machinery operational around the clock, and PCB repair service is a key element of our offerings. Printed Circuit Boards (PCBs) form the backbone of many industrial systems, and their efficient repair ensures minimal downtime.

Having worked extensively in the field, our team has gathered substantial expertise in addressing PCB issues swiftly. The intricate nature of these components demands a precise approach, and we pride ourselves on our ability to repair a wide variety of PCBs, restoring them to optimal condition. This dedication to excellence underscores our commitment to our clients’ operational success.

Common Issues and Solutions in PCB Repair

Damaged Traces

One of the frequent problems we encounter is damaged traces on the PCB. These thin lines of copper act as electrical highways, and any disruption can cause a significant malfunction. At AFSub Soft, we employ specialized techniques to repair these traces, ensuring a reliable connection is re-established. Our technicians utilize precision tools to meticulously reconstruct trace lines, often using conductive ink or fine wire to bridge gaps.

Defective Components

Component failure is another challenge we often face. Whether it’s a capacitor, resistor, or integrated circuit, each part plays a crucial role in the functionality of the PCB. Our approach involves a detailed diagnostic to identify faulty components quickly, followed by sourcing and replacing them with high-quality equivalents. This process ensures longevity and reliability of the repaired board.

Corrosion and Oxidation

Corrosion is a silent killer of electronics, often caused by environmental factors. We’ve seen cases where corrosion has severely affected the PCB’s performance. Our team uses advanced cleaning methods to remove corrosion and protect the board from future damage. Preventative treatments and coatings are then applied to mitigate risks and extend the life of the PCB.

Our Proven Process for PCB Repair

The PCB repair service we provide is underpinned by a structured process designed for efficiency and success. Our stringent methodology ensures each board receives the care and attention it requires.

Initial Assessment

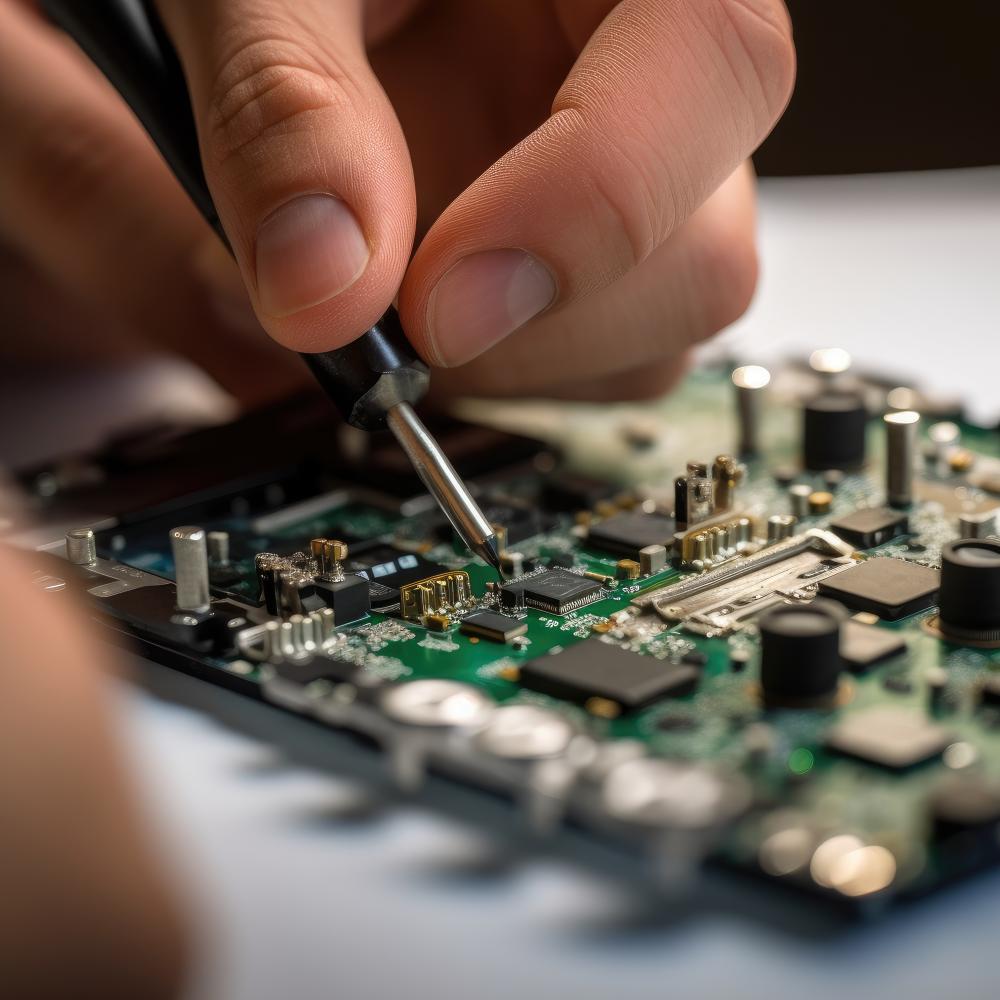

Every repair begins with a thorough assessment. Our team meticulously inspects the PCB for visible damage and uses state-of-the-art diagnostic equipment to detect hidden issues. This comprehensive examination allows us to map out the necessary steps for repair.

Repair and Testing

Once the problems are identified, we proceed with the repair. Whether it involves trace repair, component replacement, or thorough cleaning, our technicians employ their vast experience to restore the PCB. Post-repair, each board undergoes rigorous testing under simulated working conditions to ensure it meets the required performance standards.

This approach not only resolves existing issues but also helps prevent future failures, contributing significantly to the overall reliability of industrial systems.

Enhancing Equipment Longevity with Regular Maintenance

Industrial systems are akin to well-oiled machines, requiring regular maintenance to keep running smoothly. At AFSub Soft, we advocate for routine maintenance alongside our PCB repair service to extend the life of your equipment. Regular inspections can preemptively catch minor faults before they escalate into major problems.

Periodic Diagnostics

We recommend periodic diagnostics of vital components within your systems. These check-ups allow us to identify wear and tear and anticipate component failure. Such proactive measures are invaluable in maintaining peak operational efficiency and avoiding unexpected breakdowns.

Why Choose Us for Your PCB Repair Needs

Choosing the right partner for PCB repair service is crucial. At AFSub Soft, our emphasis on quality and customer satisfaction sets us apart from the rest. With years of expertise and a team of dedicated professionals, our service is both reliable and efficient.

Expertise and Experience

Our team consists of seasoned experts who bring unparalleled knowledge to every repair operation. This depth of expertise ensures that we can tackle even the most complex PCB issues with confidence and precision.

24/7 Availability

Understanding the critical nature of industrial operations, we offer around-the-clock support to address any PCB repair needs promptly. This commitment minimizes downtime and ensures your systems are back online as quickly as possible.

Customer Trust and Testimonials

The trust you’ve placed in us over the years is a testament to our unwavering dedication. Our customers’ testimonials highlight our consistency in delivering exceptional service, fostering long-lasting partnerships with our clients. This trust is built on our promise of quality and timely service, setting a benchmark in the industry.

Innovations and Future Trends in PCB Repair Service

The field of PCB repair is ever-evolving, with technological advancements continuously reshaping the landscape. As a leader in the industry, AFSub Soft stays at the forefront of these changes, integrating cutting-edge technologies to enhance our repair capabilities.

Advanced Diagnostic Tools

New diagnostic tools are emerging, offering more precise fault detection and analysis. These innovations allow us to refine our repair processes further, ensuring quicker turnaround times and more effective solutions for complex PCB problems.

Materials and Processes

Developments in materials science are introducing new repair techniques and materials that offer enhanced durability and performance. We are actively incorporating these advancements to ensure our repairs not only meet but exceed industry standards.

Our commitment to embracing these innovations ensures that our clients continue to receive the most modern and effective solutions available, keeping their operations running smoothly in an ever-changing industrial landscape.

How much does PCB repair cost?

PCB repair costs can vary widely depending on the complexity of the problem, the type of PCB, and the extent of the damage. At AFSub Soft, we first conduct a comprehensive assessment of the board to determine the issue and provide an accurate quote. Generally, the more intricate the circuit and the more significant the damage, the higher the cost will be. However, investing in PCB repair can be more cost-effective than replacing an entire system. If you’re dealing with budget constraints, consider the potential for reduced downtime and improved equipment longevity that comes with professional repair. Customers often ask us about cost-effectiveness, and we reassure them that our services are designed to extend the life of their industrial equipment with minimal disruptions.

How much does it cost to repair a PCB board?

Repairing a PCB board can range in cost depending on several factors. Typically, the cost is influenced by the board’s complexity and the parts needed for repair. At AFSub Soft, we strive to provide an economical solution by using high-quality replacements and efficient repair techniques. For instance, a simple trace repair might be on the lower end, while a board with significant component damage can be more expensive. We always recommend reaching out for a personalized quote based on your specific situation. It’s worth noting that investing in quality repair services can lead to long-term savings by preventing future failures and maintaining optimal performance.

Can a damaged PCB be repaired?

Yes, a damaged PCB can often be repaired, especially when handled by experienced professionals like our team at AFSub Soft. We regularly deal with issues such as damaged traces, defective components, and corrosion, which we resolve through precise repair techniques and high-quality component replacements. Our proven process includes initial assessments, meticulous repairs, and rigorous testing to ensure reliability. For example, if you’ve experienced machinery downtime due to a damaged PCB, our team can help get your systems up and running efficiently, often turning around repairs faster than anticipated.

Can a burnt PCB be repaired?

Repairing a burnt PCB is challenging but not impossible. At AFSub Soft, we assess the damage to see if it’s feasible to restore the board to functionality. While severe burning might require a replacement, many cases allow for repair, such as replacing burnt components or reconstructing damaged traces with precision tools. We’ve encountered situations where clients thought their gear was beyond recovery, yet with our expertise, we’ve managed to salvage the board and save on replacement costs. If you’re dealing with a burnt PCB, don’t lose hope–consult with us to explore potential repair options.

What are some common misconceptions about PCB repair?

One misconception is that PCB repair is always costly and not worth the investment. In reality, professional repair services can be quite cost-effective, extending the lifespan of your equipment and preventing costly downtime. Another false assumption is that all damaged PCBs need to be replaced. However, many boards can be repaired adequately, restoring them to full functionality. At AFSub Soft, our aim is to provide transparent information and effective solutions, dispelling myths about the ineffectiveness of repairs and emphasizing the benefits of regular maintenance and timely interventions.

Why is regular PCB maintenance important?

Regular maintenance is crucial for preventing unexpected breakdowns and extending the life of your PCB and related equipment. By conducting periodic diagnostics and routine inspections, issues can be identified and addressed before they lead to significant problems. At AFSub Soft, we advocate for a proactive approach to maintenance, as it helps identify wear and tear early, ensuring that your industrial systems operate at peak efficiency. Think of it as providing your machinery with a regular health check-up to keep it running smoothly and reliably.

What are some future trends in PCB repair services?

The field of PCB repair is evolving rapidly, with new trends making services more precise and efficient. Innovations in diagnostic tools and materials are at the forefront, allowing for more effective fault detection and improved repair strategies. At AFSub Soft, we stay ahead by integrating cutting-edge technologies into our repair processes, ensuring that our clients benefit from the latest advancements. For instance, advancements in materials science are providing new repair methods that enhance durability and performance. As these trends continue to develop, they promise to make PCB repair faster, more reliable, and more cost-effective. Are you curious about how these innovations might impact your industry? We’d love to hear your thoughts or answer any questions you might have.

Resources

- National Institute of Standards and Technology – Official website of NIST providing standards, measurements, and calibration information.

- Environmental Protection Agency – Homepage of the EPA offering resources on environmental regulations and protection.

- World Health Organization – Official website of the WHO providing global health information and resources.