Expertise in PLC Repair Services

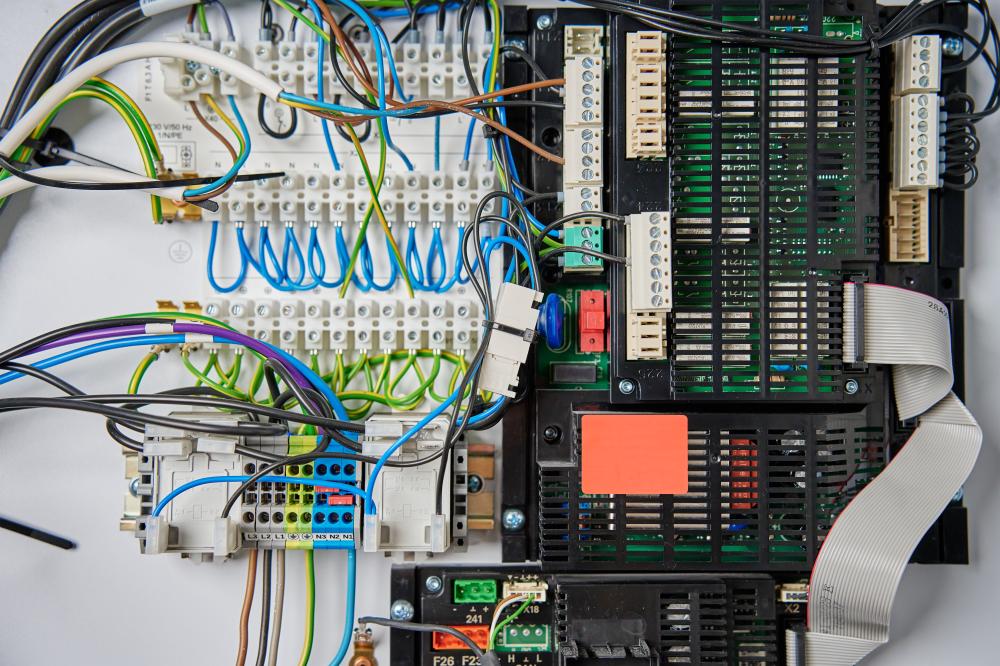

When it comes to repairing programmable logic controllers (PLCs), expertise is crucial. At AFSub Soft, we pride ourselves on being the premier provider of PLC repair services in India, with a team of professionals skilled in diagnosing and addressing complex electronic issues. Our technicians have years of experience handling a wide array of PLC models, ensuring that we can fix problems efficiently no matter the brand or complexity of the device. This expertise translates into reduced downtime and cost savings for our clients, allowing them to focus on their core operations without ongoing disruption.

Why PLC Repair Services Matter

In an industrial setting, the failure of a PLC can lead to significant downtime and financial loss. PLCs are integral to automation systems, controlling processes that directly affect productivity. Repair services ensure minimal disruption, restoring operations swiftly and reliably. By choosing to repair rather than replace PLCs, businesses can save as much as 80% on costs, allowing these savings to be reinvested into other essential areas. Furthermore, a quick diagnosis and repair by AFSub Soft’s team can extend the life of your existing equipment, enhancing return on investment.

Another critical aspect of why PLC repair services are invaluable is the preventive maintenance they inherently provide. Regular check-ups and timely repairs prevent minor issues from escalating into major failures. This proactive approach not only saves time and money but also ensures safety and compliance with industry standards. AFSub Soft’s commitment to adhering to the highest repair standards ensures that all serviced PLCs meet or exceed original performance specifications.

The reliability and longevity of industrial equipment are greatly enhanced through professional repair services. When systems run optimally, companies can maintain consistent production schedules, meeting client demands without unexpected interruptions. Thus, investing in professional PLC repair services is not just a cost-saving measure but a strategic decision to safeguard your business operations.

Services Offered by AFSub Soft

AFSub Soft offers a comprehensive suite of services for various industrial electronics, beyond just PLC repair services. Our expertise extends to VFD drive repair, which is essential for maintaining the variable frequency drives that control motor speed and torque. By keeping these components in peak condition, we help clients optimize energy consumption and improve operational efficiency.

Additionally, we provide HMI repair services, crucial for ensuring the seamless interaction between operators and machinery. A malfunctioning HMI can hinder productivity and pose safety risks, making our prompt repair services integral to uninterrupted operations. Soft starter repair services are also part of our portfolio, which are vital for reducing mechanical stress on motors and ensuring smooth start-up processes in equipment.

Benefits of Choosing AFSub Soft

Choosing AFSub Soft for your PLC repair services comes with a myriad of benefits. Our 24/7 availability guarantees that you can access help whenever you need it, reducing downtime and maintaining productivity. We understand that time is of the essence in industrial operations, and that’s why our quick response times are designed to keep your systems running smoothly.

Our trusted reputation is built on years of successful repairs and satisfied clients, who appreciate our commitment to quality and reliability. The guarantee we provide on our repair services gives our customers peace of mind, knowing that their equipment is in expert hands. Additionally, our dedication to continuous improvement ensures that we stay ahead of industry trends, incorporating the latest technology in our repair processes to deliver unparalleled results.

Another benefit of partnering with AFSub Soft is the personalized service we offer. Our team takes the time to understand each client’s unique needs, tailoring our repair strategies to best fit their specific circumstances. This customer-centric approach not only builds long-term relationships but also assures clients of our unwavering commitment to their success.

Anecdotal Success Stories

One notable instance demonstrating the impact of our PLC repair services involved a large manufacturing client in Mumbai. Their production line was halted due to a PLC failure, impacting their ability to meet a significant order deadline. Our team was called in late at night, and within a few hours, we diagnosed and repaired the fault, enabling production to resume by morning. The client was able to fulfill their order commitment, avoiding potential penalties and maintaining their reputation for reliability.

Another success story comes from a textile manufacturing company that faced recurring breakdowns due to faulty HMIs. After several unsuccessful attempts with other service providers, they turned to AFSub Soft. We diagnosed underlying systemic issues and implemented a robust repair and maintenance plan. Since then, their equipment has operated seamlessly, contributing to an increase in production output and a significant decrease in downtime.

The Process of PLC Repair

The process of PLC repair at AFSub Soft begins with a thorough evaluation of the malfunctioning unit. Our technicians perform a detailed analysis to identify the root cause of the problem, drawing on their extensive knowledge of industrial systems. This phase is critical, as it ensures that the subsequent repair addresses the core issue, rather than just the symptoms.

Following diagnosis, our team applies specialized techniques and state-of-the-art equipment to execute the repair with precision. The repaired unit undergoes rigorous testing to ensure it meets optimal performance standards before being returned to the client. This commitment to quality control is a hallmark of AFSub Soft’s service, ensuring reliability with every repair.

The Impact of Technological Advancements

Technological advancements in industrial automation have made PLCs more complex and efficient, posing new challenges for repair services. AFSub Soft stays at the forefront of these developments, continuously updating our knowledge and tools to handle the latest models and technologies effectively. Our technicians receive regular training to keep their skills sharp, ensuring that they can tackle even the most sophisticated PLC systems with confidence.

The integration of IoT and AI into PLC systems is changing the landscape of automation, requiring repair services to remain adaptive and innovative. At AFSub Soft, we embrace these changes, using them as opportunities to enhance our service offerings and deliver even greater value to our clients. By staying ahead of the curve, we ensure that our clients can leverage new technologies to their fullest potential, without fear of unexpected breakdowns or costly repairs.

Client Support and Customer Service

At AFSub Soft, exceptional customer service is the cornerstone of our business. We prioritize communication with our clients, ensuring they are informed at every stage of the repair process. Our dedicated support team is always on hand to answer questions, provide updates, and offer expert advice, fostering a partnership built on trust and transparency.

In addition to our repair services, we offer insightful recommendations for preventive maintenance and system upgrades, helping our clients stay ahead of potential issues. Our goal is to empower our clients with the knowledge they need to make informed decisions about their equipment, thereby enhancing their operational strategies and achieving long-term success.

Can a PLC be repaired?

Absolutely, a PLC can be repaired, and this is something we specialize in at AFSub Soft. Over the years, we’ve seen a wide range of issues from minor glitches to major operational failures. The key lies in a thorough diagnosis. For example, a client once brought in a PLC with intermittent failures. Our team quickly identified a faulty power supply component and replaced it, restoring the PLC to full functionality. Repairing a PLC is often far more cost-effective than replacing it, saving our clients up to 80% on costs. Have you ever considered how much downtime a faulty PLC could cost your operation?

What is the life expectancy of a PLC?

The life expectancy of a PLC is generally around 10 to 15 years, depending on the operating environment and maintenance practices. At AFSub Soft, we emphasize the importance of regular maintenance and timely repairs to maximize this lifespan. I recall a manufacturing plant we assisted where the PLCs were over 12 years old. Through our preventive maintenance services, we identified key components that needed upgrading, thereby extending the life of their systems significantly. Have you scheduled maintenance checks for your PLCs recently?

How do you solve a PLC problem?

Solving a PLC problem starts with a detailed analysis of the unit to identify the root cause. At AFSub Soft, our technicians have years of experience with diverse PLC models, so we begin by examining the fault codes and conducting hardware inspections. We once had a client with a complex fault where communication between modules was lost. By using specialized diagnostic tools, we pinpointed the issue to a damaged communication port and fixed it promptly. Have you noticed any unusual error codes on your PLCs lately?

What is a PLC maintenance technician?

A PLC maintenance technician is a skilled professional responsible for maintaining, troubleshooting, and repairing PLCs. At AFSub Soft, our technicians are trained to handle the latest technological advancements in automation. They are crucial in ensuring that systems run smoothly and efficiently. Imagine a technician as a doctor for your PLC; they diagnose issues, perform preventive checks, and ensure your system’s health. Have you considered the value a specialized technician could bring to your facility?

How do technological advancements impact PLC repair?

Technological advancements have significantly impacted PLC repair by introducing more sophisticated and complex systems. At AFSub Soft, we continuously update our skills and equipment to keep pace with these changes. The rise of IoT and AI has led us to adapt our methodologies to service advanced PLCs effectively. This continuous learning is what sets us apart, ensuring we provide cutting-edge solutions. Have you integrated any new technologies in your PLC systems recently, and how might these impact your repair needs?

What are the benefits of choosing AFSub Soft for PLC repair?

Choosing AFSub Soft for your PLC repair needs offers numerous benefits. Our 24/7 availability ensures that we’re always ready to address urgent issues, minimizing your downtime. Our technicians are not just skilled but passionate about delivering quality service, as evidenced by positive client testimonials. For instance, we once helped a textile firm struggling with frequent breakdowns due to faulty HMIs, and now their operations are seamless. Isn’t it reassuring to have a partner you can rely on for industrial electronic repairs?

Resources

- Industry Week – Industry Week is a leading source of manufacturing news, trends, and insights for professionals in the industrial sector.

- Rockwell Automation – Rockwell Automation is a global leader in industrial automation and information solutions, providing cutting-edge technologies for businesses.

- International Society of Automation (ISA) – The International Society of Automation (ISA) is a nonprofit organization that sets the standard for automation by providing industry-leading technical resources.

- National Fire Protection Association (NFPA) – The National Fire Protection Association (NFPA) is a global nonprofit organization dedicated to eliminating death, injury, property, and economic loss due to fire, electrical, and related hazards.